Smart and Reliable Workforce Management!

Plan maintenance activities faster and more efficiently.

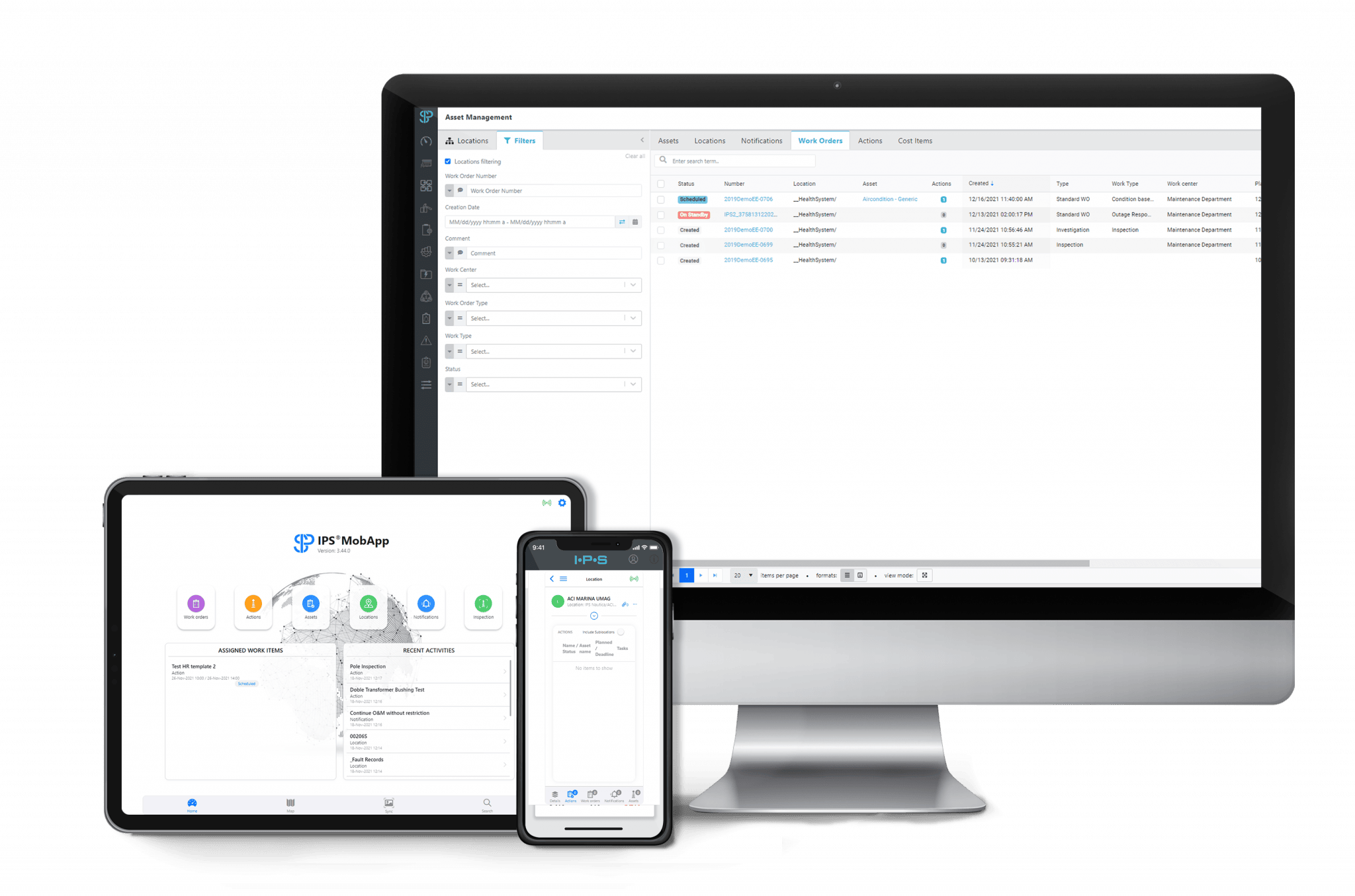

Transform your business and enhance EAM systems with advanced workforce solutions developed by IPS® Experts. Thanks to an intuitive user interface and simplicity, the IPS®MobApp WFM application is simple to use and can be used from any device.

WORKFORCE MANAGEMENT

Our leading-edge Mobile Solution IPS®MobApp WFM, with both online and offline capability and dynamically-changing work tasks and action lists, based on Field Data Collection and instant Asset Analytics, providing superior predictive maintenance capability, as well as Voice Recognition (Luna) and Machine-learning, Asset Nameplate and Condition Photo Recognition and Analysis.

Workforce management is easier with an advanced mobile platform IPS®MobApp WFM. Our leading-edge Mobile Solution, with online and offline capability and dynamically- changing work tasks and action lists, based on Field Data Collection and instant Asset Analytics, provides superior predictive maintenance capability and Voice Recognition. Machine-learning (IPS®LUNA), Asset Nameplate, and Condition Photo Recognition, along with Analysis, are just some of the already built-in features.

Online and offline capabilities

Realtime Analytics

Designed for field users

How does Workforce Management work in IPS®?

An essential part of Workforce Management is planning. With integrated planning wizard, short- and long-term plans are created in a matter of minutes. With advanced filtering, users can select asset groups, apply action templates and let the system do the magic. Planning wizard is a tool that organizes all activities and defines execution dates, with predefined maintenance cycles and tolerances. Assets are paired with action templates, and a maintenance plan is created. Workforce Management can be enhanced with the IPS® Asset Investment Planning solution.

After the plan is created, with triggers in IPS®SmartGridDI, work orders are created, and notifications are triggered. These triggers may launch various types of follow-up actions such as e-mail notifications, web alerts, or a work order action generation. Save valuable resources by effective work scheduling and control.

Executing maintenance is the last step, where the fieldworker gets the job done. With advanced IPS®MobApp WFM, all data is directly synchronized from the central database. Field workers are always up to date with work orders and tasks. Also, an overview of maintenance action history and asset location-related tasks are available.

IPS® MODULES FOR WORKFORCE MANAGEMENT

IPS®SYSTEMS are distinguished by modular design. Customers can add individual module groups according to functional requirements and perform the gradual implementation of the system – starting with basics and implementing full functionality step by step.

IPS®MobApp WFM

IPS®ENERGY

IPS®LUNA

IPS®SmartGridDI

IPS® Calculation Studio

GET IN TOUCH

Effective workforce management and planning is just one click away. Get in touch with IPS® Experts, and learn how to increase productivity and lower the costs with better planning of maintenance and workforce activities.