Asset performance management – data input

One of the most important questions Electric Utilities must consider with their maintenance strategies and asset performance management systems is data input. Which data we should reflect, when assessing asset condition and importance factor? Nowadays, there are many available data sources within enterprises:

- Enterprise Asset Management (EAM) systems,

- IoT and historical data,

- External sources (weather and climate data),

- Financial, safety, and environmental data (regulatory frameworks),

- Network performance data,

- Unstructured data…

Asset Health Index

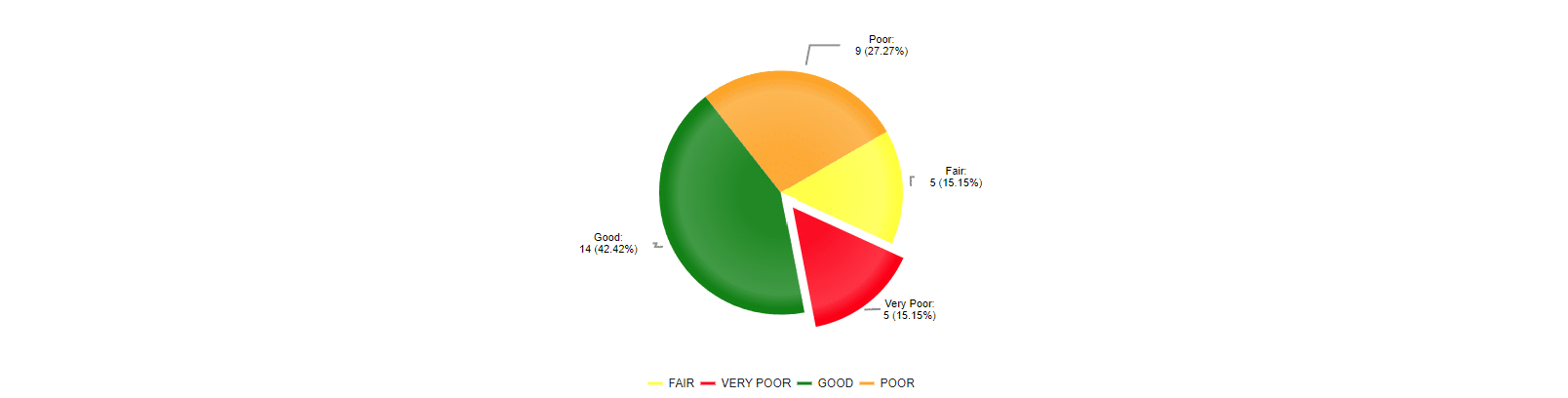

Asset Performance Management systems will gather and analyze selected data, and then assemble the Asset Health Index (AHI) to evaluate asset condition. IPS®APM uses AHI (Asset Health Index) for asset health performance, condition monitoring, and AHI estimation.

Asset Health Index will analyze asset conditions through different parameters and provide sophisticated algorithms and analytical tools for reliable asset health calculation, health trend, and breaking point (remaining asset live) prediction.

Industry experience and libraries?

Along with existing in-house data, Electric Utilities should look for industry-specific asset libraries, which integrate observations and experience from maintenance and malfunctions into their asset management system. In that way, the Asset Performance Management system will benefit from continuous updates and improvement, leading to better risk evaluation.

Industry-specific libraries and data can enable faster deployment, integration of existing sources, and better project implementation through:

- Improving asset algorithms,

- Proactive handling of low-quality and insufficient data,

- Reflecting data designed and specialized for industry-specific assets,

- Introducing ML and AI technology into new projects.

Selecting maintenance strategy and input data.

In electric Utilities, maintenance is a wide field of interrelation: technical requirements and specifications that correlate with financial aspects and operational constraints. Therefore, a perfect universal maintenance strategy cannot be defined because it depends on the specific demands, experience, and profile.

No matter which maintenance strategy is chosen, the goal is to achieve maximum reliability and safety at the lowest possible cycle cost. The maintenance can be conducted either as:

- Time and event-based maintenance (corrective),

- Risk-based maintenance (preventive),

- Condition-based maintenance (utilizing the Asset Health Index),

- Predictive (PdM) and prescriptive maintenance (PM forecasting).

The main scope of PdM is to determine the component or equipment state (condition) on a continuous basis before a possible breakdown occurs.

Below is example input data that we should evaluate when assessing asset condition factor:

- Asset age,

- Spare parts available and skilled staff available,

- Cost level,

- Specific asset monitoring data,

- Atmospheric stress exposure,

- Operational safety and experience,

- Pollution Experience,

- Indoor / Outdoor,

- Physical Condition – (Test result data) …

We also must assess importance (risk) factor and consider parameter data like:

- Component criticality,

- Asset availability and impact,

- System unavailability,

- Backups exist,

- Value of protected object,

- Type of object…

You can also check, how Tenaga Nasional Berhad (TNB), largest electricity utility in Malaysia and a leading utility company in Asia implemented Asset Performance Management solution and which data inputs they integrated.